Product Description

Curtain wall is usually composed of aluminum alloy, glass, stone and other materials. It is a lightweight wall with a decorative effect commonly used in modern large and high-rise buildings. It is also the exterior wall enclosure of the building. It has the functions of lightweight, flexible design, protection from wind and rain, beautiful decoration, safety, and reliability. Therefore, in modern architecture, curtain walls have gradually become an important building material and are widely used in high-rise, commercial, public, and other buildings.

Benefits of aluminum glass curtain walls include:

1.Material savings of up to 15%

2.Faster project completion times

3.Cheaper than traditional pressure bar systems

4.This curtain wall aluminum profile features a stick or panel mount with no exposed attachment fasteners. It can be used in captured glass or double-sided structural silicone glass configurations. This zone-sealed, pressure-balanced system offers superior performance and value.

We offer aluminum profile glass curtain wall solutions

1.Curtain wall with visible frame

2.Curtain wall with hidden frame

3.Curtain wall with horizontal visible frame and vertical hidden frame

4.Vertical visible frame and horizontal hidden frame curtain wall

5.Unitized curtain wall

6.Curtain wall with thermal break

We can produce glazed aluminum curtain wall system in various finishes according to your drawings and samples.

We also double-check the quality of our products to extend their life and achieve your satisfaction.

Product Detail

Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

Length | 5.8M or Customized. |

Thickness | 0.4mm-20mm or Customized. |

Application | Building and Construction and Decoration. |

New Moulds | Opening new mould about 7-10 days. |

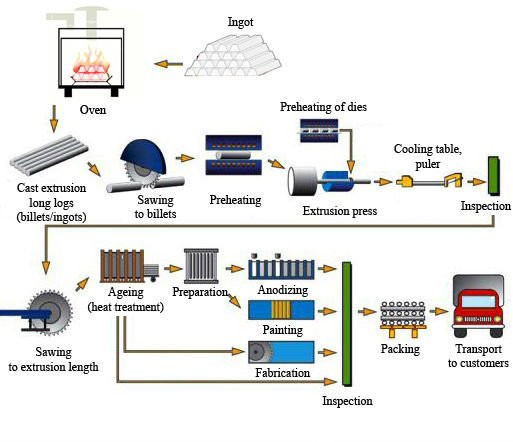

Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

Certification | 1. ISO9001-2008/ISO 9001:2008; |

Payment | 1. T/T: 30% deposite, the balance will be paid before delivery; |

Delivery time | 1. 15 days production ; |

OEM | Available. |

Product Application

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

We chat